In the last couple of posts I’ve described the reason for taking apart the rear suspension on bowtie6. I had to send the coilovers back to the manufacturer for servicing and sure enough, after a few days they arrived back in as-new condition. This morning, I started cleaning all the hardware and springs followed by a dry-run: installing the coilovers on the rear suspension (without springs) and going through the entire range of motion of the axle using my jack. I just wanted to make sure nothing was binding or out of alignment. All checked out, so time to quit farting around and get down to business…

As you can see in the featured picture above, I have a small can of fresh anti-seize handy. I use anti-seize on pretty much all bolts I use. I cringe when I watch “restoration” shows on TV and see very expensive cars assembled without a single bolt treated with anti-seize. So why make such a big deal? Anti-seize is a very cheap insurance for preventing a bolt from galling. Especially when dealing with aluminum parts as in this case, where the entire coilover body is aluminum alloy. Furthermore, there will be a day when all bolts will be taken apart. Anti-seize is just an easy way to prevent unnecessary binding.

I started applying anti-seize on the shock body, the spring seat and the lock nut. I added anti-seize to the spring seat where the spring rests simply to help the spring edge slide a little easier when tightening up the seat. Ditto for the lock nut. It is very important to note that anti-seize will act as a lubricant and as a result, don’t forget to keep that in mind when tightening bolts with a torque wrench. Bolts treated with anti-seize will have a higher clamp load than untreated ones. OK, enough “theory” for today’s post – LOL!

I started applying anti-seize on the shock body, the spring seat and the lock nut. I added anti-seize to the spring seat where the spring rests simply to help the spring edge slide a little easier when tightening up the seat. Ditto for the lock nut. It is very important to note that anti-seize will act as a lubricant and as a result, don’t forget to keep that in mind when tightening bolts with a torque wrench. Bolts treated with anti-seize will have a higher clamp load than untreated ones. OK, enough “theory” for today’s post – LOL!

The spring seat ready to be tightened. The lip has threads and they actually start before the spring even starts to compress. Duh! That is the idea! No more spring compressor.

The spring seat ready to be tightened. The lip has threads and they actually start before the spring even starts to compress. Duh! That is the idea! No more spring compressor.

Here is the assembly chucked up on the vise using a set of soft jaws to prevent from damaging the bottom bearing. Using a special wrench, I started tightening the spring seat until I had enough threads left to safely hold the lock nut.

Here is the assembly chucked up on the vise using a set of soft jaws to prevent from damaging the bottom bearing. Using a special wrench, I started tightening the spring seat until I had enough threads left to safely hold the lock nut.

This is a closeup of the top mount: the black “U-shaped” tab is an extension of the frame. If you look closely, there are two delicately machined spacers on either side of the inner “U-shaped” mount. My cousin Jim made those on his lathe and it is just a shame these gems are hidden from view. This is not store-bought stuff!

This is a closeup of the top mount: the black “U-shaped” tab is an extension of the frame. If you look closely, there are two delicately machined spacers on either side of the inner “U-shaped” mount. My cousin Jim made those on his lathe and it is just a shame these gems are hidden from view. This is not store-bought stuff!

This picture shows the spherical rod end on the top mount of the coilover as well as the dampening adjustment knob (more on that later). The top mount uses the spherical rod end to give room for the coilover to float. The bottom mount is just a regular polyurethane lined fixed bearing. The picture below shows the black polyurethane bearing.

This picture shows the spherical rod end on the top mount of the coilover as well as the dampening adjustment knob (more on that later). The top mount uses the spherical rod end to give room for the coilover to float. The bottom mount is just a regular polyurethane lined fixed bearing. The picture below shows the black polyurethane bearing.

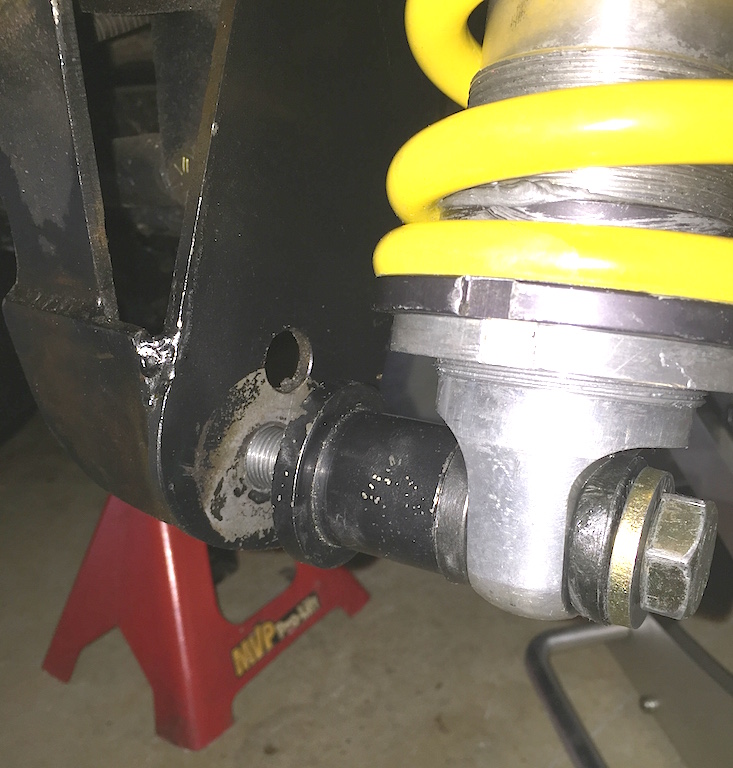

The bottom mount does not float. Instead, it is fixed against the mount extending from the axle. If both mounts were fixed then the coilover would bind when the axle moved one side higher than the other. You can also see the axle mount with some paint missing. That comes from the spacer that lines up the coilover with the top mount.

The bottom mount does not float. Instead, it is fixed against the mount extending from the axle. If both mounts were fixed then the coilover would bind when the axle moved one side higher than the other. You can also see the axle mount with some paint missing. That comes from the spacer that lines up the coilover with the top mount.

And finally, on this picture you can see the machined spacer. And now, an explanation on ride height…

And finally, on this picture you can see the machined spacer. And now, an explanation on ride height…

I’ve been asked to find a way to “lower” the ride height on the rear suspension on bowtie6. Unfortunately, there is no way to lower things any more than where they are today. As you can see in the picture above, I am already using the lowest opening on the lower mount bolt.

One feature of coilovers is adjustment of ride height. Sure, this is an option. However, the way it works is this: the more the spring seat is tightened, the more the spring compresses and ride height increases. The less the spring seat is tightened, the less the spring compresses and the ride height lowers. In my case, the spring seat is out as far as it can go. Anything else would not give me enough room for the lock-nut to thread into.

And here is the result! All ready to go for a test drive!

And here is the result! All ready to go for a test drive!

I realize bowtie6‘s rear ride height is a tad on the “high” side. It would be nice to drop it another inch or so. However, since I am running larger than stock rear tires they could hit the inner fenders. This would not be good for the paint! Another idea to carry out the lowering would be to order new, shorter coilovers. However these coilovers are not cheap and I rather not have to get another set.

And now an “extra”! I do not endorse products by name – I just don’t like to advertise for “free” – but there are exceptions. Last week, I had this arrive after placing an online order:

This is a 1/2 inch, 20 Volt DeWalt electric impact wrench. I bought this unit from the “Factory Outlet” store – it is online and they have some great prices on “refurb” units. I also have a 3/8 impact wrench, a 6.5″ saw and an LED light plus the rechargeable battery station. They all share the bottom rechargeable 20V Max battery. My air wrenches are now retired! These rechargeable electric tools are awesome! I highly recommend them.

This is a 1/2 inch, 20 Volt DeWalt electric impact wrench. I bought this unit from the “Factory Outlet” store – it is online and they have some great prices on “refurb” units. I also have a 3/8 impact wrench, a 6.5″ saw and an LED light plus the rechargeable battery station. They all share the bottom rechargeable 20V Max battery. My air wrenches are now retired! These rechargeable electric tools are awesome! I highly recommend them.

Last but not least: I took bowtie6 for a spirited drive once all was tight and torqued to spec. I had to fiddle with the rebound damping setting a bit but the difference is certainly noticeable. The rear suspension is much more planted now and is a delight to push trough an “on ramp”! Nice!!

Hi, I love your Bowtie6 TR6 and appreciate all the detailed project coverage. I have a 1973 TR6, currently stock but hoping to change that. I am interested in building a “sport” touring car out of my TR6, I have a question about the front coilovers that you installed on your car. Can you tell me the brand of shock and springs you used and recommend a source for them? I am planning on converting to coilovers in the rear also and retaining the IRS. Currently looking at the Honda J37A4 V6 for power and a Honda S2000 AP2 6 speed transmission. Like your car, mine also has the factory hardtop and dealer installed A/C. I have already otained a couple of R22 LSD(3.54) rear ends. I’ve also been looking at the RATCO differential crossmember and rear spring tower units. Any advise or recommendations will be appreciated. Thanks

Thank you for your comment Ted!

The engine setup you are describing will be interesting indeed. I own a 2003 Honda S2000, so I am very familiar with the 6 speed gearbox. Granted mine is an AP1 but they are similar – I think the ratios are a little different but basically they are extremely well made gearboxes and silky smooth to boot. Very nice choice! Plus in your case, that would make perfect sense since you are planning to use the Acura V6 60 degree engine. The angle will give you enough room, hopefully you won’t cut into the body too much.

However it was my experience that using true coilovers with the original IRS trailing arms did not work so well. There was a certain point in the travel of the trailing arm “arc” that caused the coilover to bind. We fought this plenty and eventually I was not exactly satisfied with the way it worked. BTW, the “original” shocks from Triumph are rubbish therefore that was not an option for me. All that and the extra weight of an IRS “chunk” (diff) eventually made me decide upon the straight axle. Yes, it is not as glamorous as an IRS but the extra-long factory trailing arms did not work so well.

I must say, the LSD rear axle I have matches my needs perfectly. I could not be happier, but as always “your mileage may vary” and if the IRS is what you want then so be it. It is your money after all. Just remember that the IRS (and halfshafts/cv’s) will become the weak link in your system. Whatever you do – do your homework!

I would love to see pictures of your setup. Send me some and I will be very happy to post them here on the blog! Perhaps someone else might find this of interest. My email: info at bowtie6 dot com.

Cheers!

Thanks for the comments and advice. I’ll keep you informed as I make progress. Currently trying to locate the a good J35A and the AP2 6 speed. Several available on Craigslist and I am making contact with the sellers. Hoping to find both with less than 80k miles.

Cool!! Please keep me posted – I’ll post pictures of your setup.

Your thread here is exactly what I need at the moment. I am dealing with tire and wheel sizes on my TR6, and improving my rear suspension, which feels like pizza dough at the moment. For power, I have a slightly modified HI compression version of the Buick 215 linked to a BW T50 5-speed transmission. It puts out a lot of power, and the rear of the car tends to squat a lot when I accelerate with any seriousness. I found some springs with a few extra turns on them, and I’m hoping that will help. That, and replacing the OE lever shocks with conventional shocks. Does this sound like I’m on the right track? I’m using the stock IRS.

Hello Ron – and thanks for your comment.

I am not surprised with your suspension woes and the “squat” you describe. This is a shortcoming on the IRS for sure. The lever shocks can (and often do) fail and become very weak. This and the added power of your Buick engine cause the squat. Not good.

Look into some decent springs and perhaps having the lever shocks rebuilt. I know there are folks that will rebuild them and change the dampening oil with something more viscous. However, they do have their limitations and this is why I ditched them as quick as possible.

Good luck!