I’ll ask again, how much does a TR6 weigh?

This has been a question in my mind ever since we fitted the new frame and engine to bowtie6. Well today I finally was able to find out. The result was a great surprise.

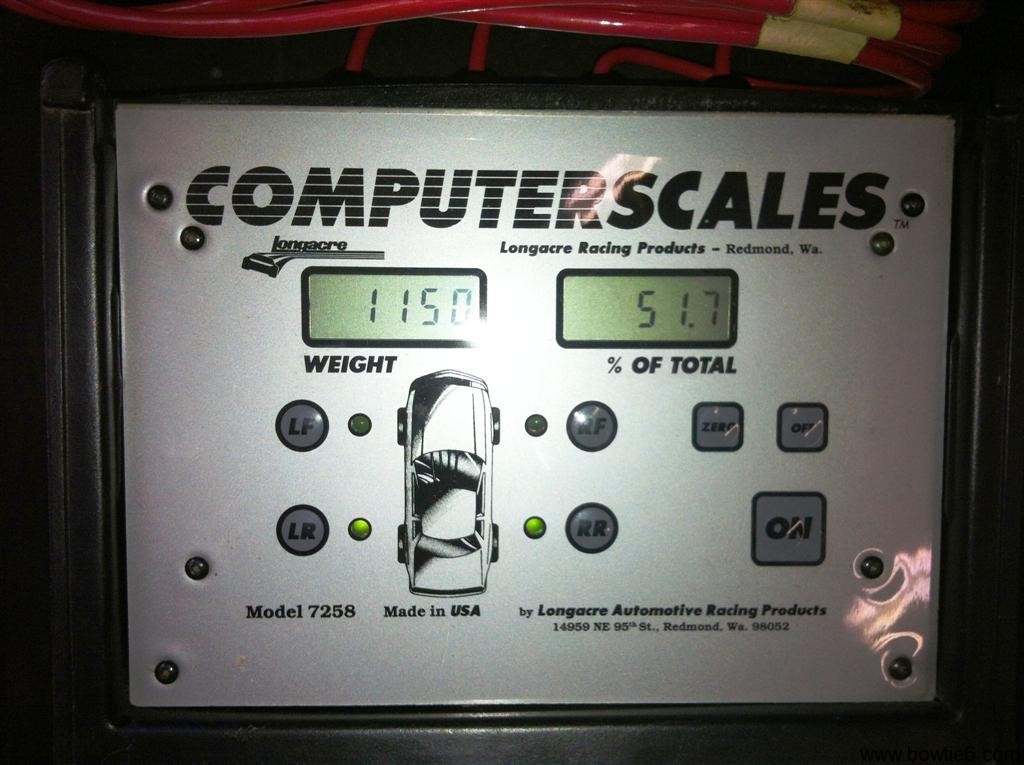

Along with a full tank of fuel and the hard top in place we took our first set of numbers. The following pictures show front and rear total weights.

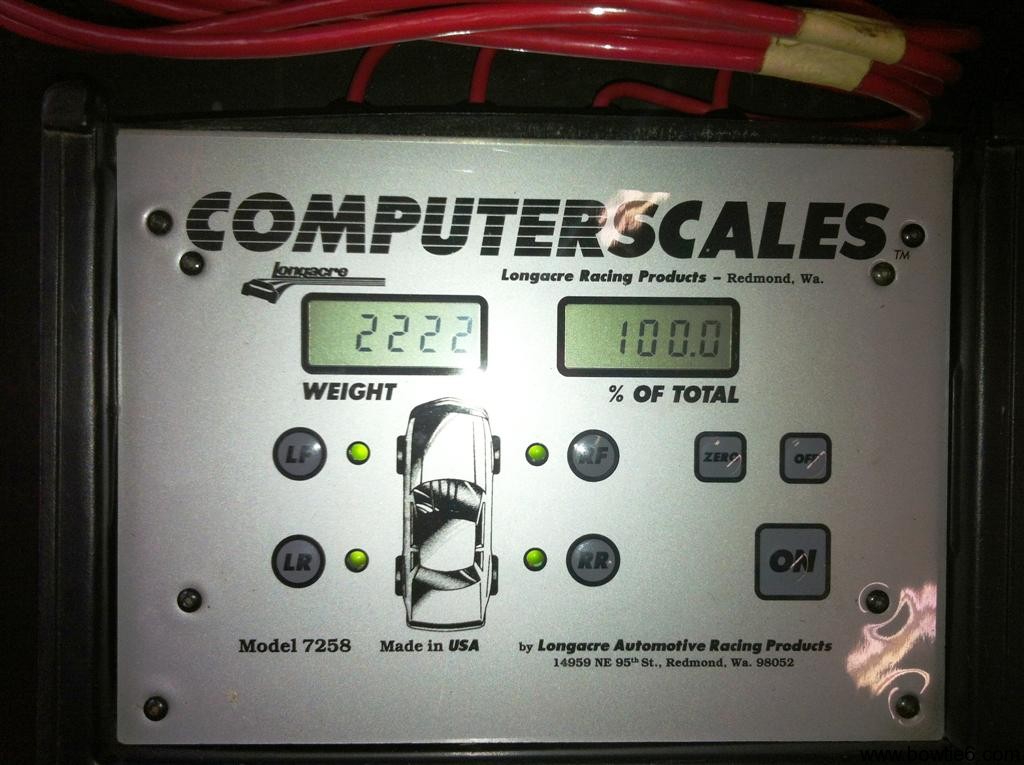

Here is the total:

Not too bad – 2,222 lbs and a 48.2% front / 51.7% rear bias.

We were curious about the weight of the factory hard top. Well I can conclusively state the Triumph factory hard top weighs in at about 65 lbs. Granted mine has had a few changes done. I have added a layer of Dynamat Extreme inside however, I removed all the chrome trim. So at the end of the day, I guess this would be about equal.

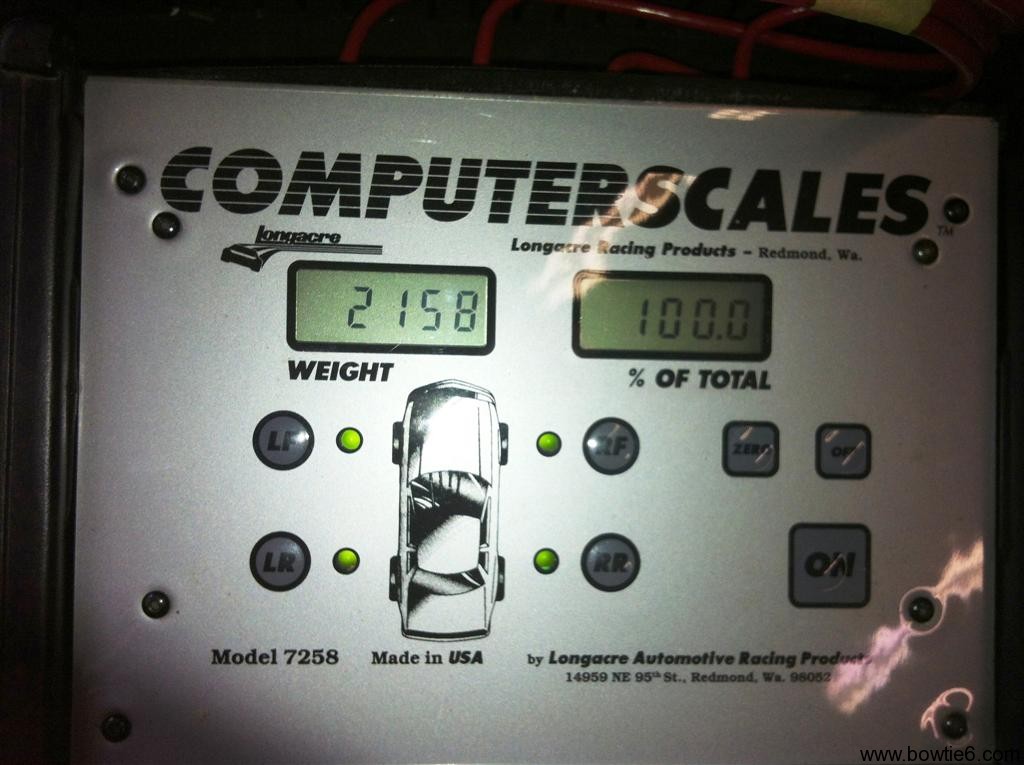

Here is the total without the hard top in place:

With the hard top removed, total weight is 2,158 lbs and a 49.3% front / 50.6% rear.

Next thing I need to do is put bowtie6 on a dyno and measure just how much horsepower we are putting down on the pavement. In stock form, the 2.4 Ecotec in a Solstice/Sky produces 177 hp. That is using the restrictive factory exhaust and the factory tune which is optimized for economy. In bowtie6‘s case, we have tuned the PCM to produce power at the expense of economy (duh!), so we are far above from the stock value. How much? That we need to find out.

Regardless, this is all quite impressive. It would have been nice to be closer to 2000lbs but 2,158 is not shabby at all. I guess I should not have used all that Dynamat! 🙂

Oh and I found a prior post I had made regarding how much my cousin Jim’s TR4 weighs – to read that post CLICK HERE.