Today, I bring to you my personal NOCO Genius10 Battery Charger review. But first, lets get this straight: if you are a regular reader of my blog you know I don’t like to mention products by name and only on certain exceptions do I do a “review”. Having said this, I thought this post might come in handy for other car enthusiasts with more than one machine in their stable.

Today, I bring to you my personal NOCO Genius10 Battery Charger review. But first, lets get this straight: if you are a regular reader of my blog you know I don’t like to mention products by name and only on certain exceptions do I do a “review”. Having said this, I thought this post might come in handy for other car enthusiasts with more than one machine in their stable.

Thanks to Covid19, my driving has been reduced dramatically. The S2000 and bowtie6 have not been out in many weeks and given the weather has been nice, I wanted to take bowtie6 out for a ride. I turned the key, pressed the start button and all I got was that sickening “brrrp-brrrp” sound. The Red Top Optima just did not have the balls to get the Ecotec to turn over. Fine, got the keys for the S2K and tried it. Pressed the red Start button and ditto – “brrrp-brrrp”. Damn.

Yes, I have procrastinated for many years and been cheap in not having a decent battery charger/tender. I would normally just borrow my cousin Jim’s charger and solve the problem. This time, I did a little research and decided to invest in my own charger/tender. Logged into Amazon and found very good reviews on the NOCO Genius10 charger/maintainer. The price was actually discounted from what the NOCO website has it listed, so I ordered one. If it didn’t work, I could always send it back, right?

The box came with the charger, a separate cord with clamps and a little instructions booklet. If you are wondering why the separate cord with clamps is configured that way, well… It is because there are other corded adapters available. For example, there is a pigtail with an OBD-II plug that will charge the battery through the OBD-II port.

Here is a closeup of the clamps. You can see the clamps are held in place by button-head screws that if removed, turn the cable into something that can be permanently attached to the battery posts. Yes, there is a separate accessory available for purchase, that provides this functionality. There is also another adapter that can be added that even has a little charge gauge of sorts. Pretty nifty.

Charger Impression

The charger is made well. It is quite heavy and easy to use. The little plugs used to connect the accessory pigtail are OK. They could “click” a little better but for what they are, they will suffice. Finally, the cables are long enough although I did use a short heavy gauge extension cord to go from the receptacle to the charger.

The charger is made well. It is quite heavy and easy to use. The little plugs used to connect the accessory pigtail are OK. They could “click” a little better but for what they are, they will suffice. Finally, the cables are long enough although I did use a short heavy gauge extension cord to go from the receptacle to the charger.

The interface is handled by one button that when pressed correctly enables the Genius10 to charge pretty much any kind of battery. There are a number of icons that show what is going on. And, on the back of the unit the sticker clearly states “Made in Vietnam”.

Pressing the single control button cycles through the different battery types and voltages available. This charger will handle lead batteries as well as AGM batteries like my Red Top Optima. The charger sells for about $100.

I started with the lead battery setting on the S2000’s battery and after about 4-5 hours, the green LED finally reached the “done” setting. I clicked on the button to make it jump to the AGM setting and then moved over to the Optima in bowtie6. This took a little longer, but eventually the green LED reached the “done” setting. Needless to say, both cars started right up and all I can say is that I should have bought this device a long time go.

If I had a complaint to make is the flimsy box this device comes in. You would think the folks making this charger would have included some sort of case to go with it. NORCO makes cases, but they are right pricey – actually a third of what the device sells for. You would think with a premium product like this, some sort of case should have been included. I suppose Mick had it right, “You can’t always get what you want, but if you try sometime, you get what you need”.

Now some other thoughts about things in general, in no particular order…

This weekend has come and gone; the days just seem to run into each other thanks to our pandemic. The new “normal” is grim, I know. But… Finally we get to watch live NASCAR at Darlington and that gave a feeling of somewhat “normalcy” if you will to this Sunday afternoon. Gosh it sure is nice to hear the engines run again. Hard to believe this May won’t have the glorious F1 machines in Monaco nor we watch the spectacle of engines wailing at the Brickyard…

Hope those of you reading this post are doing well. I’ve been watching a lot of old movies on TCM these past few weeks. There have been some good films indeed. Matter of fact, they even showed 2001 A Space Odyssey – one of my favorites – and HAL doing his thing. I’ll date myself, but I remember actually watching that movie at the theater back in the day. Awesome movie – just don’t try to make any sense out of it. And while we are at it, try asking your Echo Dot, “Alexa close the pod bay doors”… She don’t like that so well! <grin>.

I made another trip to see my mom this past weekend and this time I drove the Camaro SS. I track mileage on Fuelly.com and much to my surprise, it had been 2 months to the day since I had fueled up the Camaro. How time goes by.

Not sure if you are a fan of podcasts, but there are a few that I have subscribe to that are excellent. Among them is “Throughline” from NPR, “A History of Now” from Marketplace and one called “The Cold War: What We Saw“. Depending on the subject matter, the episodes can vary in length but the content is fantastic. Especially “Throughline“.

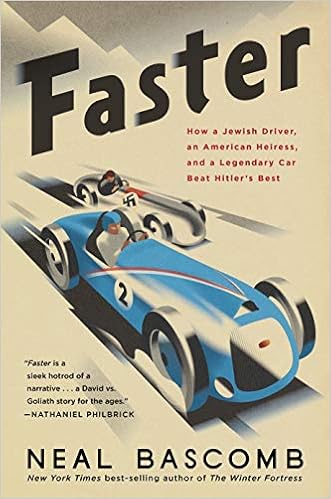

Finally – on the car theme – I’m really enjoying a new book I downloaded to read on my iPad. The book is titled “Faster” and so far, it is excellent. This book is about racing in the age prior to World War II and mixes the flamboyance of the early GP drivers and their cars and the upcoming Nazi regime with the rise of AutoUnion and Mercedes in the world scene with their mighty Silver Arrows.

Finally – on the car theme – I’m really enjoying a new book I downloaded to read on my iPad. The book is titled “Faster” and so far, it is excellent. This book is about racing in the age prior to World War II and mixes the flamboyance of the early GP drivers and their cars and the upcoming Nazi regime with the rise of AutoUnion and Mercedes in the world scene with their mighty Silver Arrows.

The book takes a little time to get started, but once you get past the opening chapter or so, it starts to really get interesting.

And that is it for this weekend. Stay safe!