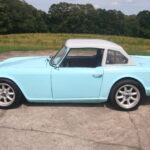

This is my cousin Jim’s Ecotec Powered Triumph TR4. Currently for sale on Bring a Trailer – CLICK HERE.

This is my cousin Jim’s Ecotec Powered Triumph TR4. Currently for sale on Bring a Trailer – CLICK HERE.

Jim passed away about a year ago. He was a machinist and built many cars in his shop in Greenville, SC. This was his personal car, having built it about 14 years ago. The car weights 2100 pounds – read more HERE. The odometer in the speedo states 21,784 miles. The speedo was brand new when installed at the time the car was restored (zero miles). The paint scheme was inspired by the 1959 ex-works Sebring Sprite – Jim owned a Bugeye Sprite back in the day, and he used to talk about it a lot!

The body shell was locally sourced in Greenville SC and was for the most part rust-free. The body was stripped, primed and painted in Jim’s shop. Bad spots were fabricated and repaired then welded where needed. The hood and the trunk lid are all aluminum, formed with an English wheel in his shop. The hood and trunk lids both have custom fabricated stays. Finally, a custom hardtop was also made from aluminum. The car does not have the convertible soft top frame nor soft top.

Inside, the car has a roll bar mounted to the frame. In addition to the hard top, the car comes with an “Alumakini” that can be used instead of the hard top (read more HERE and HERE). In the nose of the car is a custom aluminum air dam, stainless mesh, and aluminum front grill. At the rear, the bumper is custom made from aluminum, as well as the tail light bezels. All body panel fit is consistent and there are no big gaps between body panels.

The car rides on a set of 185/55R16 Firestone FR740 tires mounted on Panasport 16″ wheels – read more HERE.. Wheels are free of scars or curb rash. The tires have code “V698 ADR 2820″”; no cracks on the walls; no cracks on the tread. The 2820 date code indicates these tires were manufactured in the 28th week of 2020.

Jim made a new frame from square steel tubing to match the dimensions of the original frame. The frame was designed to hold Triumph TR6 IRS front suspension components, TR6 steering rack, Aldan coil overs (front and back) and a modified rear axle. The rear axle housing is a narrowed 8” Ford with Motive posi-traction and a 3.80 to 1 ratio. Axles are special order Moser. The rear end is held in place by a 4-link design. Once all was fitted, it was taken apart and painted black and re-assembled.

The frame was also designed to hold an LE5 2.4 GM Ecotec 4-cylinder motor. The motor and transmission came from a 2006 Pontiac Solstice. The engine/gearbox was purchased from a lot of engines/gearboxes sold by Mallet Cars. Mallet at the time was doing LSx conversions on Solstice/Sky cars, and we bought 3 “take out” motors with almost zero mileage. The engine and transmission in Jim’s car originally had less than 20 miles on it. The engines came with the Solstice harness, and that was later modified at Jim’s shop to fit the engine compartment of the TR4. The gearbox is an AISIN 5-speed, as fitted to the Solstice/Sky. The engine did not come with an ECM, so an ECM from a 2.4 Cobalt SS was used instead. Using HPTuners, the base Solstice 2.4 tune was downloaded to the ECM as a base and then, further tuning was performed. The E67 ECM fits inside a custom aluminum box in the engine compartment. Various relays, circuits and main fuse panel can be found there. The Ecotec has variable-valve timing (VVT) and it is noticeable when accelerating.

The engine is for the most part stock. However, the Solstice intake is too big so a custom aluminum intake was fabricated by Jim. The new intake was mated to a GM sourced flange that matches the intake ports. Four aluminum runners were welded and the new intake made to match. The original fly-by-wire electronic throttle was adapted to the new intake. Due to space restrictions, the headers were fabricated from stainless steel and welded to a GM sourced exhaust flange, including provision for an O2 sensor. This was welded to a low restriction muffler and a single stainless pipe exiting at the rear of the car. Just because we wanted to be different, the end holds two Supertrapp diffusers with removable rings. All this gives the TR4 a very distinctive exhaust note. The driveshaft is custom-made by a local manufacturer and adapted to fit the AISIN 5 speed gearbox and narrowed Ford 8″ rear axle.

The E67 ECM has been set up by a local LSx tuner. He set the mapping based on several hours of real-time driving; the TR4 was never put on a dyno. We used HPTuners to remove VATS and also to set the engine mapping. The Solstice was originally rated at 177 HP and with the new intake, exhaust and tune, the tuner estimated it would be good for 200 HP. Perhaps this can be improved with more tuning/dyno time.

Engine cooling is handled by a Griffin Thermal Products aluminum radiator. It has a custom-made shroud holding a SPAL curved blade high-efficiency puller electric fan. The fan is controlled by a temp sensor that has a potentiometer that can be dialed in for whatever temp you want to set – this is inside the aluminum box housing the E67 ECM. At the time we put the car together we did not have the fan figured out to run with the ECM. However, with a little work, this can be achieved.

Due to the fuel requirements of the Ecotec, Jim made a new aluminum fuel tank for the TR4. This tank is fitted in the trunk and holds a modified GM LSx electric fuel pump. There is also a fuel regulator mounted in the trunk for dialing in the correct fuel pressure. If you look at the frame pictures, you can see all the stainless tubing for fuel lines and brake lines held in place with special brackets. The tank holds approximately 15 gallons.

As stated previously, the Solstice engine harness was modified to fit. The rest of the car’s wiring was made at Jim’s shop. All wires, relays, switches and breakers were sourced from Waytek. All joints and connectors were soldered and shrink wrapped. Gauges are all VDO and are fully functional. Lights all work, turn signals work and brake lights work (see video). The instruments are mounted on an engine-turned plate on the wood dash. The VDO speedo has a problem with the LCD for the odometer in that it goes blank from time to time, although to the best of my knowledge the counter continues to work. This seems to be a known issue with VDO speedos and there is a fix available on youTube – CLICK HERE for the video. I have contacted AK Speedo and they have told me their repair kit will work with the VDO speedo.

There is a fuse box mounted in the passenger’s side dash area. The master switch is on the wood dash, with a key. There is a momentary on/off toggle switch next to it, and that starts the car. There is also a switch mounted on the dash for the turn signals. Mounted underneath the edge of the dash (out of sight) is a horn push button, light switch, windshield wiper switch (with low, fast and intermittent settings), heater switch and fuel pump switch that acts like an extra security because the engine won’t run without the pump running. To turn the car off, just turn the key back to the “off” position. I provided a video that explains all this too.

There is an adjustable steering column! This is controlled by a small lever that unlocks the mounts and allows free travel up and down. The four spoke steering wheel is custom made and hand stitched. The shift knob came from brass stock, and was turned by Jim on his lathe. This compliments the very short-throw shifts by adding a little more mass to the shifter. Installed is an aftermarket street rod heater. Jim made several trap doors that are manually operated to help distribute warm air to either passenger side or driver side or defrost to the dash. The headlight high/low beam is controlled by an old-school foot switch, mounted vertically on the side because there is no room on the floor. You can press it with you left knee. There is also a lever near the heater that opens/closes the air scoop on the dash. There are factory openings behind the dash that allow air to come in.

Brake calipers are Wilwood Dynalites in the front and Nissan in the rear. The rotors are TR6 in the front and matching Nissan on the rear and they are not vented. The hand brake mechanism was fabricated and it engages he rear brake pads – however this might need to be adjusted. The brake master cylinders are Wilwood with two reservoirs and a balance bar on the pedal, so this allows bias adjustment. The clutch master cylinder is also Wilwood. Also to note, there is no power booster and as such, requires a bit of pedal pressure to stop the car. The pedal box is also Wilwood. There are pressure residual valves on both front and back brake lines. This provides a constant minute pressure reducing the amount of pedal travel. A keen eye will notice the VIN plate is not where it is supposed to be: in the area where the Wilwood pedal box is currently installed. The VIN plate has been relocated to the driver’s side door sill.

The bodywork was all done at Jim’s shop. The body was primed, sealed and painted with single-stage automotive paint in Gulf sky blue. The aluminum top is painted in gray, and has a small crack on the passenger’s side. Overall, the paint is not show quality. It has aged, shows some orange peel (mainly on the top) and has a faded patina. Perhaps in the hands of a professional, the look could be improved. There are several small cracks in the paint and there is a damaged spot on the passenger’s side door. There is a small ding on the hard top, but since it is aluminum that can be repaired with a hammer and dolly.

The aluminum top was shaped to resemble the hardtop on a TR6. The side windows do open and have a fabricated latch that allows the window to swing and lock in the closed position. The side and rear window are all acrylic, and while the side windows are still clear, the rear window is very foggy. The rear window can be replaced by removing screws holding it in place.

Jim fabricated the aluminum bomber seats. The bottoms have a rubber insert with springs around it, reminiscent of old Jaguar seats. The back-rests are held by screws. All the upholstery was made by a local automotive upholstery shop. The seats currently in the car are “version 2”: they have a longer seat cushion and are very comfortable. Included with the car will be the “version 1” seats; they have a shorter bottom cushion and different backrest design. Lap seat belts are provided and are bolted to a post extending from the frame. This is the same post that the roll bar is bolted to. There is a small box in the back deck between the roll bar posts for holding registration papers, etc. This small box is made of aluminum and has a lock, however I don’t have the key for that lock. The carpet throughout the car was sourced from a local upholstery supplier and was cut and shaped to fit.

The fuel tank is made of aluminum with an in-tank fuel pump accessible through a bolted cover. The tank holds approximately 15 gallons. The tank sits in a recess in the trunk so the bottom of the tank is not exposed. In the trunk area is a separate small fuse box that controls the rear lights as well as the fuel pump. Inside a fabricated enclosure sits a red-top Optima battery. The fuel tank has a spout with a custom turned aluminum knurled top that screws on. The trunk lid does not have a key, instead there is a small cable that extends underneath the back bumper, that when pulled, opens the latch. Closing the lid requires very little effort.

In summary, this car is a blast to drive! As shown in the photos, the car has room for improvement aesthetically. There is a lot of TLC but the mechanical systems and quality is absolutely first rate. The car has not been driven much over the past few years, and the underside could benefit from cleanup and paint to get rid of the surface rust. I have several ignition keys. The car has a clean South Carolina title and is in my name.

Finally: There is more info in the TR4 section – there are several articles about the TR4 there as well as a ton of information about my Ecotec powered Triumph TR6.

We built my TR6 first, and after Jim saw how much fun it was, he built the TR4 for himself. If you want even more information, you can read about the the TR4 and the TR6 in this blog. The details of the construction of my TR6 are very similar to the TR4 since they have the same basic frame, engine, gearbox, rear-end. The TR6 of course is a bit different but you get the idea.

If you have any questions, feel free to leave them on this page and I’ll do my best to answer them.