It has been quite some time since my last post. The bowtie6 Ecotec project is alive and well: this weekend we fired up the Ecotec for the first time! Needless to say this was quite an awesome event!!

First, here is a quick recap:

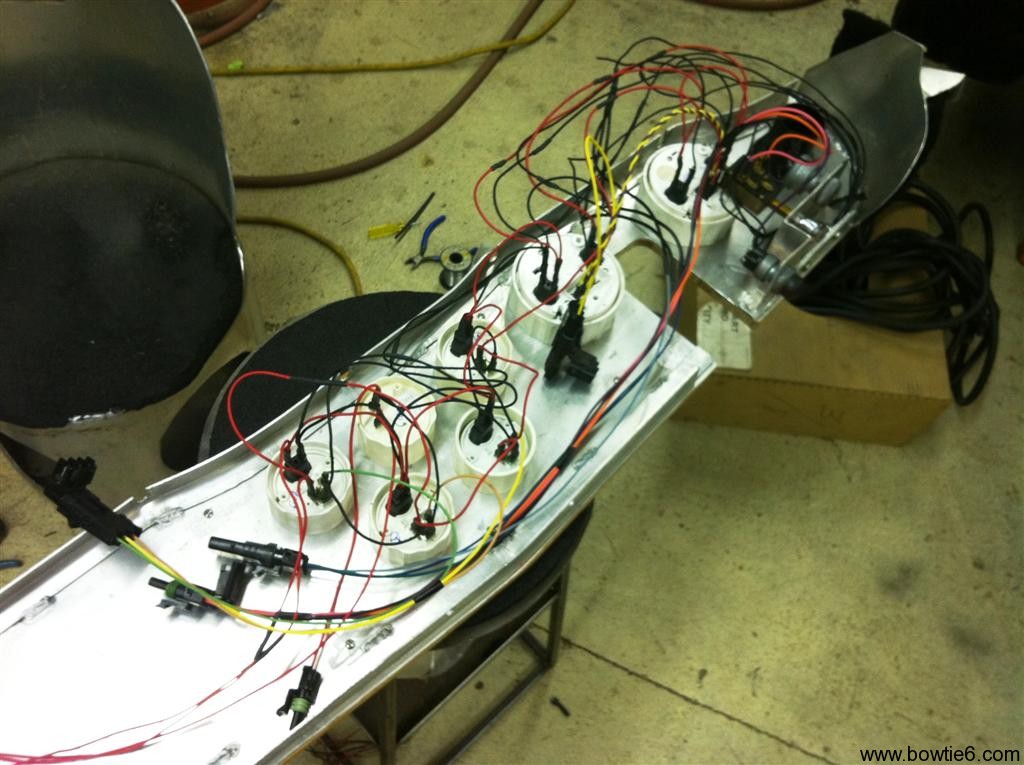

- The engine compartment has been fully wired up. There is a new engine control fusebox containing circuit breakers, relays and the ECM.

- Inside the car there is another small panel with relays and fuses controlling turn signals, park lights and main light circuits. The dash is all back together along with all gauges.

- In the trunk I have the battery mounted in a special enclosure. Yet to be done is a separate set of relays and fuses to control the stop lights and fuel pump.

We hot-wired the fuel pump for this weekend’s engine start. With the aid of my laptop and software, we disabled the VATS system by reflashing the ECM. We removed the spark plugs, turned the engine a few times and sure enough after a few seconds we had oil pressure. All good so far.

Next was fueling up and priming the pump. After running the fuel pump for a few seconds it finally “primed” itself and started pumping fuel. We attached a fuel pressure gauge and pressure looked very nice indeed.

The next step called for re-installing the spark plugs and re-installing the coilpacks. Turned the key, and pushed the button. It took a few tries but finally she fired up and ran. I hooked up the laptop again, this time to check for DTC’s. There were a few. Not good.

Turns out we had a few “issues” with the wiring. The 2.4 Ecotec has VVT on both the intake as well as the exhaust. There are two cam sensors on the top of the engine and two more on the back of the engine. The two on the back of the engine are identical to each other, and I had made the mistake of hooking up the wrong plug to the wrong sensor. This is something very unusual for GM harnesses: all plugs are unique; in this case the camshaft sensors are identical and share the same plugs. My bad.

We tried again. This time the engine ran fine but the scanner on the laptop read we were having fuel delivery issues. We tapped the throttle a few times. Coolant temps started to normally go up and we let the engine run for a few more minutes. Then things started to settle down. The fuel delivery issue went away and the engine started running better. We have encountered this issue before when re-starting an engine that has been sitting for a while and this can be attributed to an injector sticking. Once it has fresh fuel flowing, it loosens up any gummed up fuel and all is good.

We let the engine cool down and this is where things got interesting. On cold re-start the Ecotec sputtered and coughed. We noticed we had quite a few more DTC’s. This type of behaviour is to be expected. Suffice to say, that after many hours of debugging, changing a few parts around and a lot of tracing of the wiring harness all checked out. There is no issue with the ECM – we swapped the one in my cousin Jim’s TR4 and the engine behaved in the same way. So we ruled out wiring, ECM and sensors. We started looking closer…

As it turns out, the new fabricated intake had an issue. No, not a leak! We re-used the rubber intake from the donor Solstice. However, the housing for the MAF sensor is all home-made in order to allow the low restriction air cleaner element to be mounted. The size of the housing was the culprit. This was giving some false readings and this caused the ECM to make erroneous calculations regarding the air flow into the engine. After correcting the offending intake tube we fired the engine back up, and now it runs smooth as silk.

Next will be to start plugging in new values for engine run-time parameters. We’ve done some of this on my cousin’s TR4 and this along with some other tweaks will enable my TR6 to finally be back on the road.

So what is next? Now that the engine is fully operational, we are going to start hanging fenders and doors on the body shell. We anticipate having to make some special shims for the body since the frame is all new. However, the frame is perfectly level so we are hoping not to have to shim it too much!

I have some final wiring to do and once that is all complete the next step would be the maiden trip down the road. Still a few weeks away from that, but the engine runs and this has been a great weekend!

Stay tuned…