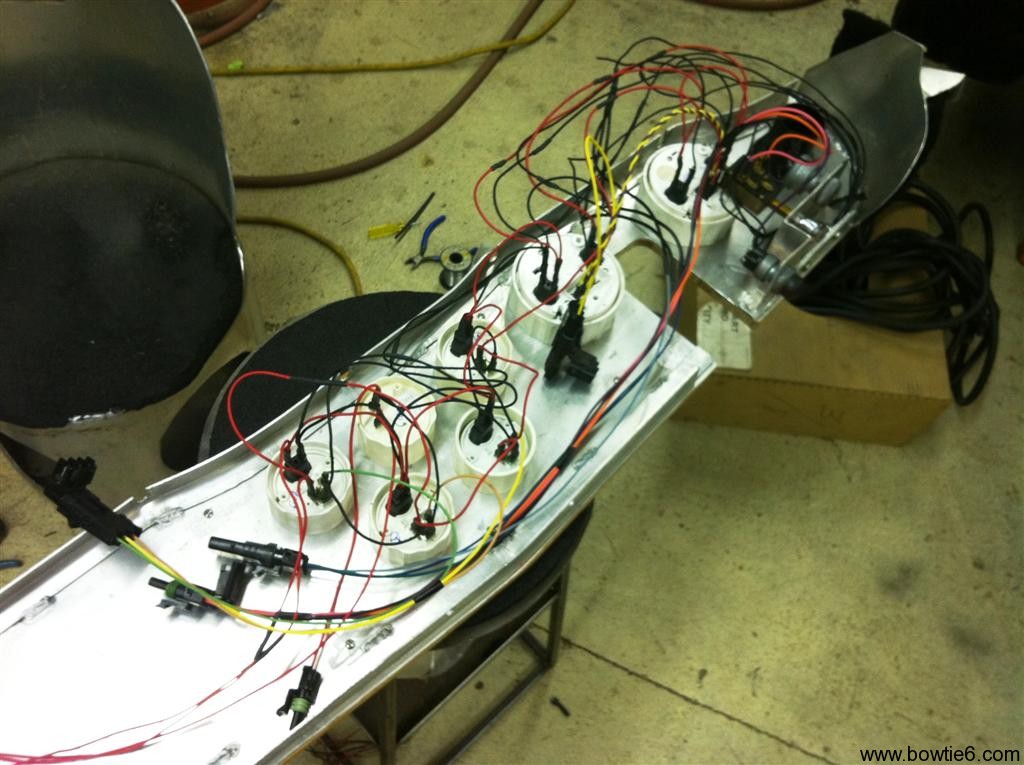

Moving along on the wiring, albeit slow. Today, I spent 6 hours working on wiring up the instruments. I was able to re-use some of the looms I made up the firs time, but had to make plenty of alterations along the way. This is what it looks like from the backside:

The gauges are VDO Vision. The have been great and are all electronic, compatible with the ECOTEC. The speedo is programmable, so it is 100% dead nuts accurate. The backing plate is aluminium and the front is made from quilted maple (I’ll have pics of the front in a later installment, once the dash is in place).

The gauges are VDO Vision. The have been great and are all electronic, compatible with the ECOTEC. The speedo is programmable, so it is 100% dead nuts accurate. The backing plate is aluminium and the front is made from quilted maple (I’ll have pics of the front in a later installment, once the dash is in place).

I realize this looks perhaps, unimpressive – but a huge amount of work has gone into making this up. Every single connector has been soldered and shrink wrapped. Since I wanted to make this so it can be removed easily, every circuit is connected to a “Weatherpack” connector. This is why it has taken so long to make.

The following picture shows the dash area in bowtie6 before the dash goes in.

- The heater has been replaced with an aftermarket unit. The “original” heater unit I used to have developed a leak. A little research found the unit pictured above which was a) cheaper and b) more efficient. Plus it is able to withstand higher pressure. This is desirable since it allows a high PSI cap on the radiator.

- The transmission tunnel has been made from scratch to match the ECOTEC’s AISIN 5 speed gearbox. It will be covered soon in Dynamat Extreme, just like the rest of bowtie6 has.

- Finally, the piece de resistance: If you look close, you can see the steering column is now fully adjustable. Yes, a special mechanism has been made by my cousin Jim that allows the column to tilt with the flick of an adjustment bar. I’ll have more on this later, once I get it all bolted back together. Trick, huh?

This wiring effort has been very time consuming, but the end result will be fantastic. There is a huge satisfaction from wiring up a car from scratch. Not many people can do this type of work – it takes patience, but it sure is a lot of fun.